EIC Solutions is a leading provider of air conditioned enclosures and patented air-conditioned transit cases. Our environmentally-controlled equipment protection solutions have been used all over the globe in a wide array of both military and industrial applications. Both the Protector Series Air Conditioned Enclosures and The Defender Series Air Conditioned Transit Cases have their advantages, but which line is best for your mobile application?

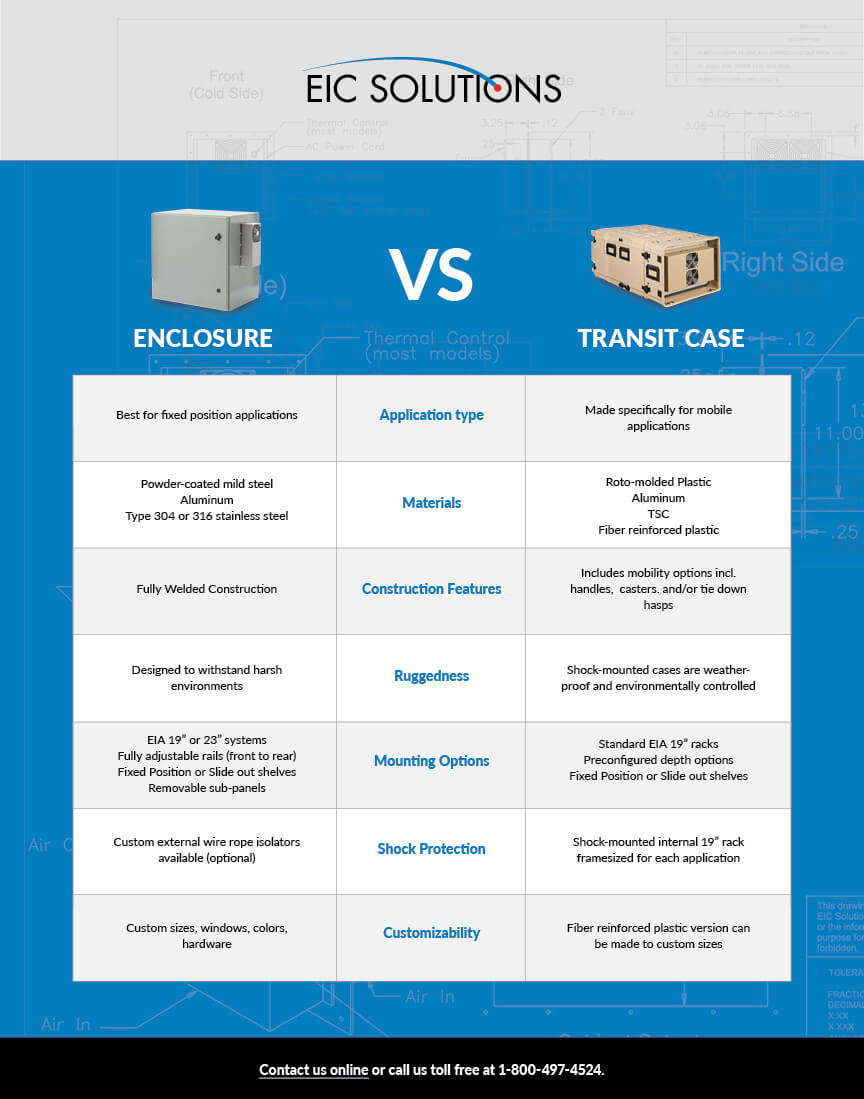

Air conditioned enclosures are available in a number of different configurations. From small wall/surface-mount enclosures to full-size rack and work-station enclosures, there is a solution for most any application. Enclosures are best suited for “fixed-position” installations, meaning that while they are mobile, they won’t be regularly relocated from position to position. These projects could be installed on a trailer, mounted to a vehicle or mounted to piece of heavy machinery. Enclosures are available in powder-coated mild steel (NEMA 4/12), aluminum, and Type 304 or 316 stainless steel (NEMA 4X). They feature a fully welded design and are designed to withstand the harshest environments. EIC’s enclosures are available in a wide variety of standard sizes as well as completely custom configurations.

EIC’s patented thermoelectrically air-conditioned transit cases are a specialized product designed specifically for mobile applications. These shock-mounted rack cases are well-suited for projects that require the regular relocation of equipment from site to site. They provide a weather-proof, environmentally controlled housing for sensitive equipment being fielded in harsh environments. They are designed with mobility in mind and can include handles, casters, tie-down hasps and more for easy transportation as well as loading and loading from vehicles. EIC’s cases are available in standard sizes constructed from roto-molded plastic, aluminum, and TSC as well as customizable configurations made from Fiber Reinforced Plastic (fiberglass in thermoset resin).

Both enclosures and transit cases are excellent mobile equipment mounting and protection solutions. However, there are several differences between the two solutions including Equipment Mounting, Shock and Vibration Protection, and Flexibility of Design.

Enclosures are available with:

One of the benefits of a transit case is the shock-mounted internal 19” rack frame. Since the case will regularly be moved, dropped, or relocated and could be subject to significant vibration, it is imperative that the equipment be shock-isolated. The size and quantity of the shock-mounts is dependent on the total weight of equipment housed within the case. Enclosures do not contain internal shock-mounting. However, vibration isolation is available for enclosures through wire rope isolators mounted to the exterior of the enclosure. This custom option will help to reduce shock and vibe to the enclosure but must be hard mounted between the enclosure and mounting surface.

EIC’s transit cases are designed to be rugged. Many case models have been tested and certified to MIL stds. These cases are regularly used by the military and have a proven track record in the field. They are designed to stack with other cases of the same design for easy transit and storage.

Transit cases can be customized if made from fiberglass, but all other materials are limited to a set number of sizes because they are a molded or stamped product.

Air Conditioned Transit Cases:

Air Conditioned Enclosures:

Both EIC’s patented Air-Conditioned Transit Cases and EIC’s Air Conditioned Enclosures can be excellent solutions for your mobile equipment protection applications. Both product lines protect and environmentally control sensitive equipment. They are available in multiple sizes and configurations with many available customizations and options. Please contact one of EIC’s knowledgeable sales engineers to determine which product line will best meet your needs.