Thermal management for sophisticated electronics in protective enclosures starts with one fundamental element: airflow. Proper airflow within and throughout the enclosure can mean the difference between successfully maintaining and cooling your sensitive electronics and risking costly downtime associated with failures.

Airflow in cabinets and enclosures can occur in a few different ways.

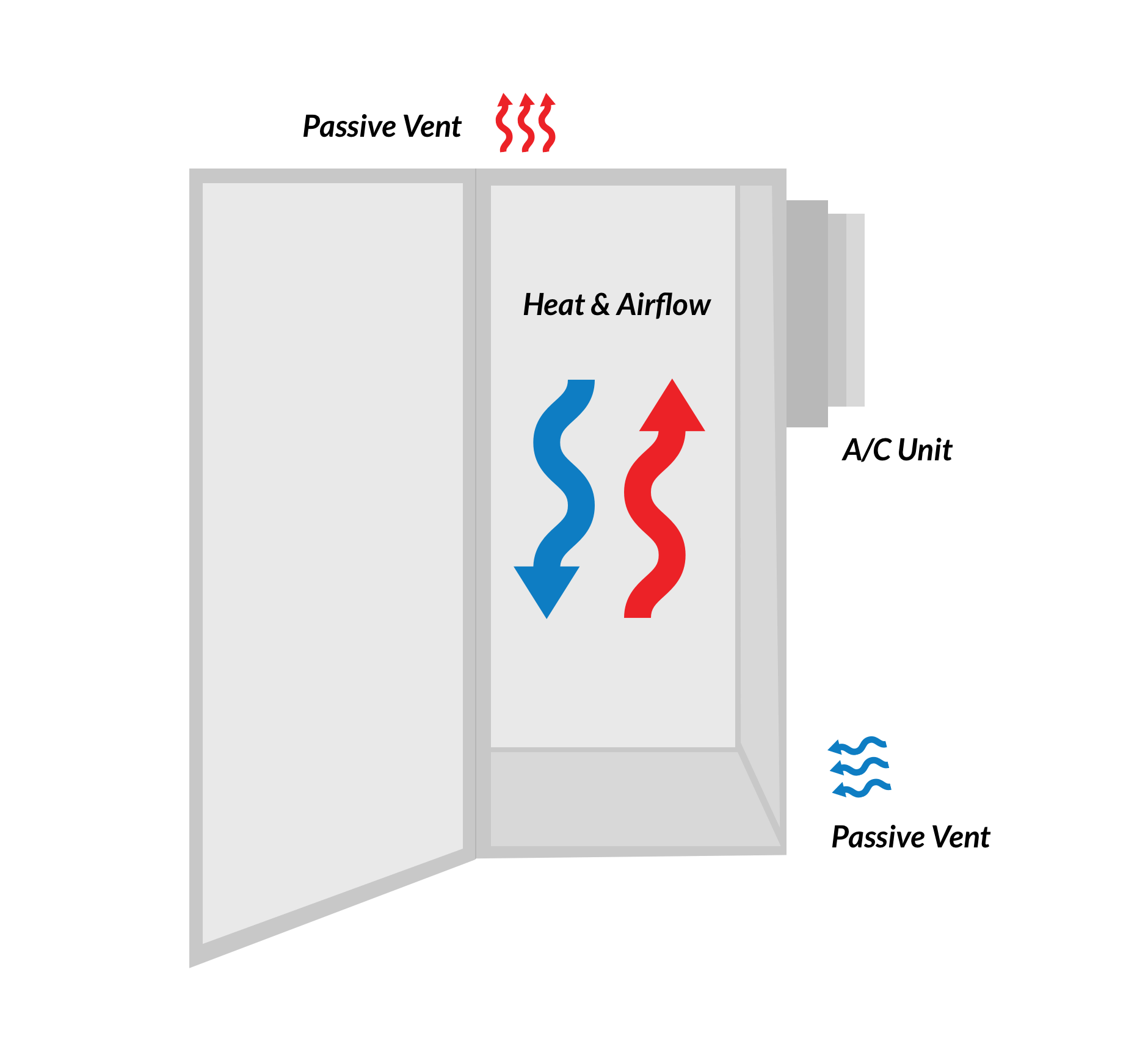

This is the most basic form of airflow. Naturally, when heat rises, cold air is pushed to the bottom of a space. Engineers should keep this in mind when laying out equipment within an enclosure. If convection isn’t properly addressed, a hot spot will form at the top of the enclosure. A solution to manage heat using natural convection is Passive Ventilation or more specifically, Louvres.

Using the same principle as natural convection, forced convection adds a fan, blower, or compressed air to force the warmed air through the enclosure and out through the upper vent (Ventilation Fan Filter Systems). Air moving devices include Fans and Blowers.

Hotspots are a common problem within electrical equipment enclosures. They can be created when heat sources within the enclosure have a lack of airflow around them. Proper spacing of equipment to provide adequate airflow and to allow for natural convection within the cabinet is crucial to the successful operation of equipment housed within. In an air-conditioned enclosure, hotspots can have a negative effect on transfer of heat through enclosure walls. When cooling the temperature within the enclosure below ambient conditions, improper airflow can allow for the formation of both hot and cold spots. The hot spots can create a dangerous environment for the equipment, whereas a cold spot will cause heat transfer through the external walls at a much faster rate. Ideally, the air temperature needs to be even throughout the enclosure to maximize the performance of the air conditioner. This is achieved through proper airflow. Insufficient airflow can have negative impacts on both housed components AND on AC performance.

There are three solutions to consider when thinking about designing enclosures to manage heat and prevent damage. These include air conditioner and component placements, along with airflow modification.

When choosing the BTU output of the AC, it is equally important to choose the proper placement of the AC on the enclosure. Placing the AC in a high position on the enclosure will take advantage of natural convection and cool the warmer air within the space as it rises. It is also imperative to keep both the intake and exhaust of the air conditioner clear of obstructions to allow for proper airflow. EIC’s ThemoTEC series Thermoelectric Air Conditioners require a minimum of two inches of clearance around any intake or exhaust; the exhaust will be better served if there are no obstructions around it.